Suitable hand protection is essential for safety, comfort and efficiency in the workplace, but finding gloves that meet all needs can be challenging. Clair Weston, Marketing Manager at uvex, addresses common issues with work gloves and highlights solutions that can help balance safety, comfort, and performance.

Managing sweaty hands

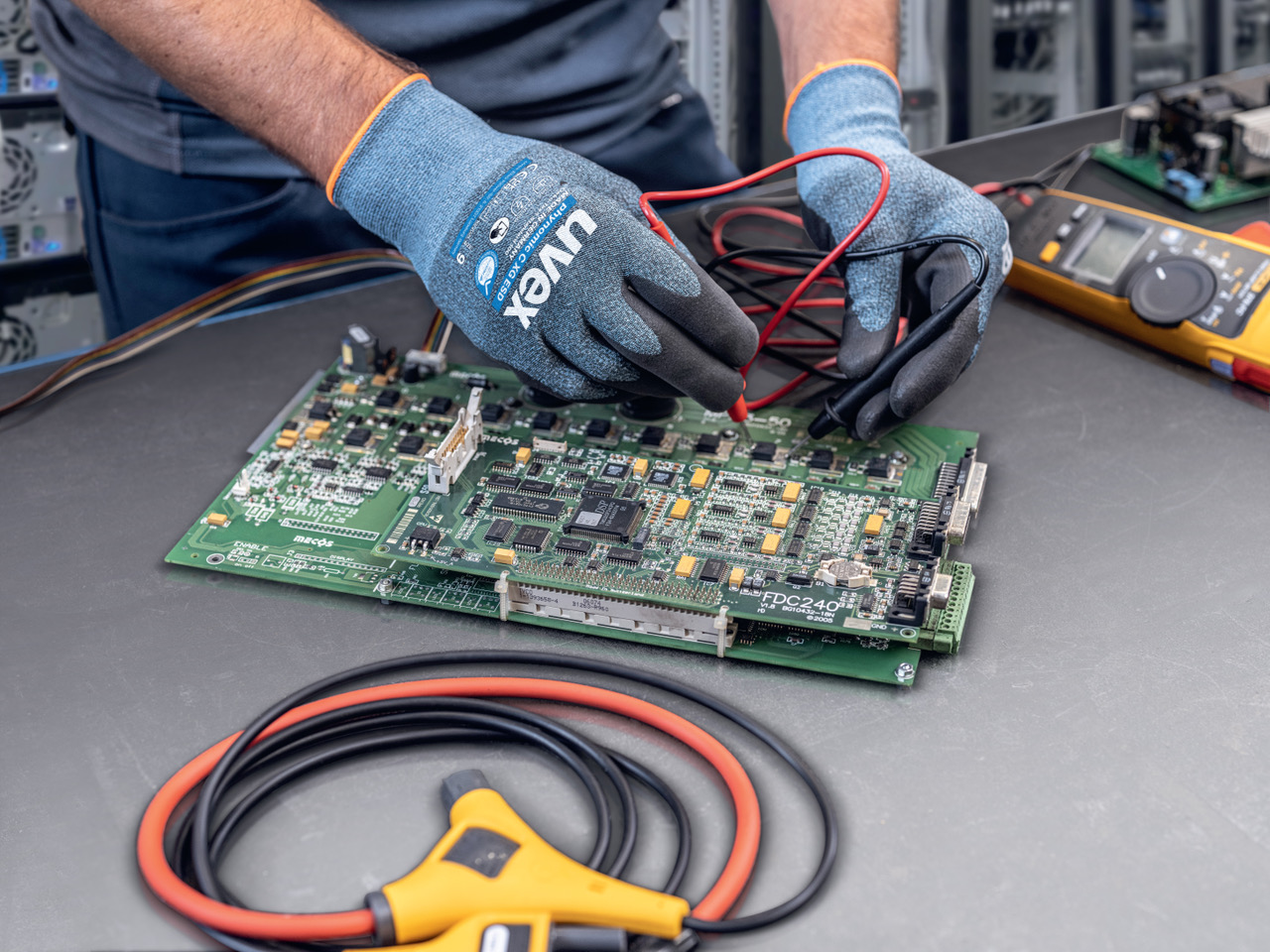

Sweaty hands inside gloves can create a slippery feeling that reduces grip and control which can be unsafe and uncomfortable, especially during prolonged use. Excess moisture can also lead to skin irritation and rashes. To tackle these issues, look for gloves designed for superior breathability, reducing moisture buildup and keeping hands dry. For example, the uvex phynomic range of gloves are designed with a breathable porous foam coating and open back ventilation, helping hands to stay dry during intense tasks or to dry quickly, so that skin irritation does not occur. These lightweight gloves prioritise moisture management, enabling workers to maintain control without a build-up of discomfort inside the glove. Meanwhile, the uvex Bamboo TwinFlex D XG gloves combine bamboo and synthetic fibres, which offer moisture-wicking properties to absorb sweat and keep hands cool. Bamboo fibers also have a smooth, silky soft feel when worn against the skin.

Importance of proper fit

Importance of proper fit

Properly fitting gloves are key to maintaining dexterity, comfort and safety. Gloves that are too tight can restrict movement, while loose gloves can lead to bunching, slipping and get caught in moving parts increasing the risk of accidents. uvex prioritises ergonomics, designing gloves that fit a wide range of hand sizes and shapes. uvex phynomic glove range provides a second skin, ergonomic fit, closely mirroring the hand’s natural contours to maximise flexibility and dexterity. Their tailored fit enhances dexterity, enabling workers to handle tools with precision. Meanwhile, the uvex bamboo Twinflex D XG glove features an adaptive fit design that moulds to the wearers contours after 3 – 5 minutes creating a custom fit. These gloves strike a balance between comfort and functionality, reducing hand fatigue over long hours of wear.

Ensuring adequate cut protection

When working with sharp tools or materials, gloves with inadequate cut resistance can increase the risk of injury. However, over-specifying cut protection can sometimes result in a loss of dexterity, making tasks cumbersome and could incur avoidable costs.

Advancements in yarn technology have introduced high-performance gloves that can deliver thinner gauge gloves with adequate cut protection without compromising dexterity while allowing employees to maintain a secure grip and precision tactility. Whereas historically, high cut protection could only be achieved with thicker gloves and older technologies such as Kevlar.

Therefore, it’s important to understand the risk and select the appropriate gloves based on the required level of cut protection, required dexterity and grip. This approach ensures workers remain both safe and efficient, reducing the risk of injury without sacrificing comfort or productivity.

Decoding safety markings on gloves

Decoding safety markings on gloves

Safety markings on gloves indicate compliance with standards for specific types of protection, such as abrasion, cut, tear or puncture resistance. These markings, typically found on the glove’s cuff, label or stamped on the back of the glove, help users identify if the gloves meet the safety, durability and longevity requirements for their tasks.

Selecting the right liners and coatings

Liners and coatings are integral to a glove’s performance, impacting everything from cut protection to abrasions resistance, grip and protection from environmental factors like oils. Understanding how liners and coatings work can help workers select gloves tailored to their tasks and work conditions.

Liners provide the glove’s first line of protection. Made from materials such as Kevlar®, Dyneema, HPPE, bamboo, cotton or synthetic fibers, they determine the glove’s cut resistance and comfort level. Some liners, incorporating bamboo, also offer moisture management and breathability.

Coatings enhance grip, improve liquid resistance, protect against environmental elements such as exposure to oils and abrasions helping the glove to last longer. Nitrile, foam nitrile and latex are popular coatings that offer different levels of grip and resistance to substances such as oils, chemicals, whilst polyurethane offers good resistance to abrasive substances.

Choosing the right combination of liner and coating ensures the gloves are both protective and functional, adapted to the specific demands of the worker’s tasks and environment.

Preventing rapid wear and tear

Frequent glove replacements due to wear and tear can quickly add up in cost and time. Investing in durable gloves designed for specific tasks prolongs their lifespan. uvex offers gloves made from high-quality materials that withstand demanding environments, providing value over time. For example, the uvex unilite 7710F is a durable double coated safety glove featuring both liquid resistance and making them ideal for heavy-duty outdoor work. This durability reduces the need for frequent replacements, ensuring cost-effectiveness.

Maintaining tactile sensitivity for precision tasks

For tasks requiring fine motor skills, gloves that reduce tactile sensitivity can hinder performance. Thick, bulky gloves make it challenging to feel and manipulate small objects accurately. In these instances look for gloves with enhanced dexterity and sensitivity. For, example, the uvex athletic lite gloves are ultra-lightweight and coated with a micro-foam layer that provides grip without sacrificing sensitivity, making them suitable for tasks where precise handling is essential. The uvex phynomic lite has a very thin yet durable design that allows workers to handle small components comfortably, preserving tactile feedback for delicate tasks.

These gloves support efficiency and accuracy in detail-oriented work, allowing workers to maintain precision without compromising safety.

Sensitive skin solutions: Solvent-free options

Workers with sensitive skin are prone to irritation and allergic reactions from gloves that contain solvents or harsh chemicals. uvex offers solvent-free gloves that minimise these risks, providing a safer option for sensitive skin. The uvex pure standard, the proDerm Institute and OEKO-TEX® STANDARD 100 certificates as well as the uvex list of 200 banned substances also ensures no harmful chemicals appear in their products. These gloves reduce the likelihood of irritation or rashes, enabling workers with skin sensitivities to wear gloves comfortably for extended periods.

Sustainability and understanding the CO2 footprint

Conclusion

Hand protection is essential for workplace safety, but finding the right gloves makes all the difference. From managing sweaty hands to ensuring appropriate cut protection, there are a wide range of gloves available that can address each challenge effectively. Investing in high-quality, comfortable and sustainable gloves can enhance worker comfort and performance can perform and reduce the risks associated with inadequate hand protection.