By Kirstie Jones, Head of Client Services and Environmental Health Expert, Navitas Safety (www.navitassafety.com)

In the dynamic landscape of food safety, ensuring that every site operates seamlessly and safely is a constant challenge. As a safety professional, I’ve experienced firsthand the immense pressure to maintain rigorous standards, keep up with ever-evolving regulations, and manage multiple sites simultaneously. The stakes are high—one oversight can lead to severe consequences, from health risks to legal repercussions.

In the dynamic landscape of food safety, ensuring that every site operates seamlessly and safely is a constant challenge. As a safety professional, I’ve experienced firsthand the immense pressure to maintain rigorous standards, keep up with ever-evolving regulations, and manage multiple sites simultaneously. The stakes are high—one oversight can lead to severe consequences, from health risks to legal repercussions.

Traditional methods of safety management, reliant on paper-based systems and manual checks, often fall short in providing the real-time oversight and accuracy we need. The struggle to compile comprehensive reports, track trends, and implement effective action plans can be overwhelming. Amid these challenges, there’s a critical need for innovative solutions that not only simplify our tasks but also enhance our confidence that every safety measure is being met, every day, around the clock.

But don’t be daunted by the prospect of adopting digital systems. These tools are designed to be user-friendly and can transform your safety management practices. Embracing digital solutions can provide immense benefits, offering precision, efficiency, and peace of mind that every safety protocol is being meticulously followed.

In this article, we’re going to dive into the transformative world of digital food safety management systems. We’ll cover:

- What is a Digital Food Safety Management System? – An introduction to digital systems and how they work.

- What Can Digital Systems Do – A look at the features and capabilities of these tools.

- The Benefits for You and Your Organisation – How digital systems enhance safety management, improve efficiency, and ensure compliance.

- Real-World Applications and Success Stories – Examples of how digital solutions have revolutionised safety practices in various organisations.

By the end of this article, you’ll have a comprehensive understanding of how digital food safety management systems can elevate your safety protocols and provide total confidence in your operations.

What is a Digital Food Safety Management System?

What is a Digital Food Safety Management System?

As a safety professional, you only have so many hours in the day, and you can’t possibly be everywhere at all times. Digital food safety management systems are like your partners in grime (sorry for the pun); they’re your eyes and ears everywhere. These systems guide your team(s) to complete checks on time and correctly each and every time, keeping you in the loop about what has been done and what hasn’t so you can take appropriate action.

What Can Digital Systems Do

Digital food safety management systems allow you to record temperature logs, food records, checks, and tasks. They also help maintain food safety policies and training records, covering all aspects of an organisation’s food safety management system. By streamlining these processes, digital systems ensure that all safety protocols are accurately followed and documented, providing you with the peace of mind that your sites are operating safely and efficiently.

Best of all, all of your reporting is done for you! Yes, more time back! As everything is digital, all of the critical safety information is transformed into handy reports and dashboards, so at a glance, you can see what needs your immediate attention. No more battling through papercuts and greasy checklists! These reports are board report-ready too, meaning you’re going to look like a safety hero with all of the data analysis done for you.

The Benefits for You and Your Organisation

Let’s be honest, we care about safety more than anything, but this sadly isn’t always shared with the same vigour by our colleagues. So, we need to make sure that safety is easy to manage.

Digital systems make completing tasks quick and efficient, prompting users on what they need to do and instantly correcting any errors. This keeps everyone focused and aligned with your safety mission without feeling nagged or burdened.

For your directors and owners, digital systems provide peace of mind by eliminating the fear of food safety breaches. Fines? Jail time? No thank you. They can have confidence in you, knowing that everything is in check, as your team(s) have their own digital safety helper to keep them accountable. Plus, they’ll love the impact on operational efficiency. Did you know businesses can save over 20% of their time through automating food safety checks?

That’s not all. With real-time safety monitoring, you can reduce stock loss (and money loss!) through 24/7 fridge/freezer temperature monitoring and instant guidance for your food service processes. This ensures nothing is over/undercooked and nothing is accepted from suppliers that don’t match your policies. This means maximising your expenditure and profits by making the most of every ingredient your kitchen purchases, processes and ultimately sells to your customers.

Let’s not forget about energy efficiency. Did you know a freezer operating just 1°C cooler than necessary can generate up to 10% more energy consumption and increase your carbon footprint? Crazy, right? You’re literally wasting money! With 24/7 appliance monitoring, you can optimise energy consumption and save thousands on your energy bills while reducing your carbon footprint. It’s truly a win-win!

Real-World Applications and Success Stories

This might all sound too good to be true but Navitas Safety is already a trusted safety partner to over 13,000 sites with 30,000 users across the globe, providing all types of organisations with digital food safety solutions and revolutionising safety practices on a worldwide scale.

Last year Netflix partnered with Navitas Safety to centralise their food safety audit processes across Europe to achieve the highest food safety standards for their workplace. Their Food and Beverage Manager told us “The main benefit is having all our audit information centralised in one place so that I can quickly understand what is happening across all our offices, within a glance. It saves me time and gives me peace of mind that everything is under control for our Employees. The platform is a great way of communicating with our several local caterers so that I can keep an eye on all things food safety. I can see what is happening, what audits have been done and which corrective actions are being taken. Most importantly, I can see any areas of improvement for the future. Having it all centralised is very helpful and helps me to report back to the wider Netflix team.”

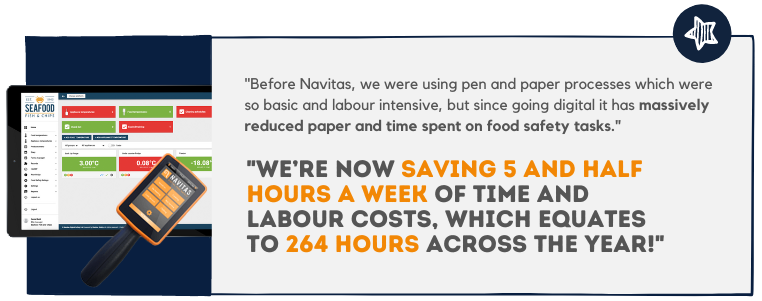

Another partner, Leicester College, one of the largest colleges in the UK, catering to over 20,000 students and 1,500 staff across 3 campuses, are now saving 5 and half hours a week of time and labour costs, which equates to 264 hours across the year. Their Commercial Catering Services Manager told us “What stands out about the system is the simplicity of it: everything is there at the touch of a button and the administration is so simple, it’s all in front of you on the screen and takes seconds. It’s incredibly accurate and the equipment and readings are so precise.”

When it comes to food safety, maintaining rigorous standards is crucial and digital technology offers a vital solution. Traditional methods, with their reliance on paper-based systems and manual checks, often fall short of providing the real-time accuracy required to ensure food safety across multiple sites. The stakes are high, and the pressure on safety professionals to avoid oversights that could lead to severe health risks or legal repercussions is immense. By leveraging digital tools, safety professionals can gain peace of mind, knowing that their operations are consistently safe and compliant.

Adopting these solutions is not just about keeping up with technology; it’s about ensuring the highest standards of food safety with greater ease and precision. With success stories from major organisations like Netflix and Leicester College, it’s clear that digital food safety systems are making a significant impact. These systems are proving to be invaluable partners in maintaining safe and efficient food operations.